E-mail: ping.wu@cszccarbide.com

Location:No.4 Xiaoshanjing Road, Zhitang Town, Changshu City, Jiangsu Province, China

In the intricate landscape of modern industry, particularly within high-end manufacturing, the "production environment" has long transcended the mere physical concept of factories and equipment, evolv...

[ Learn More 」

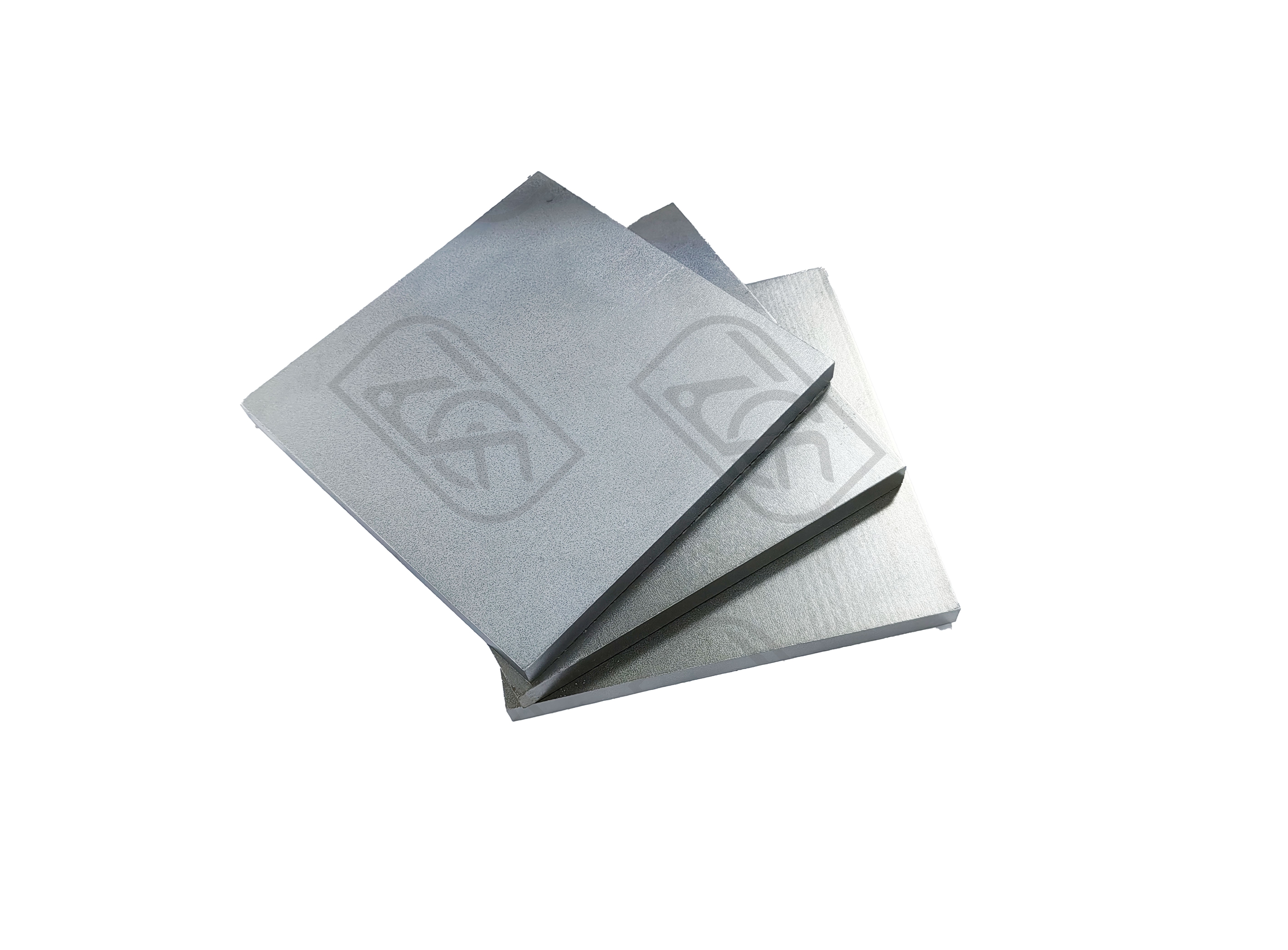

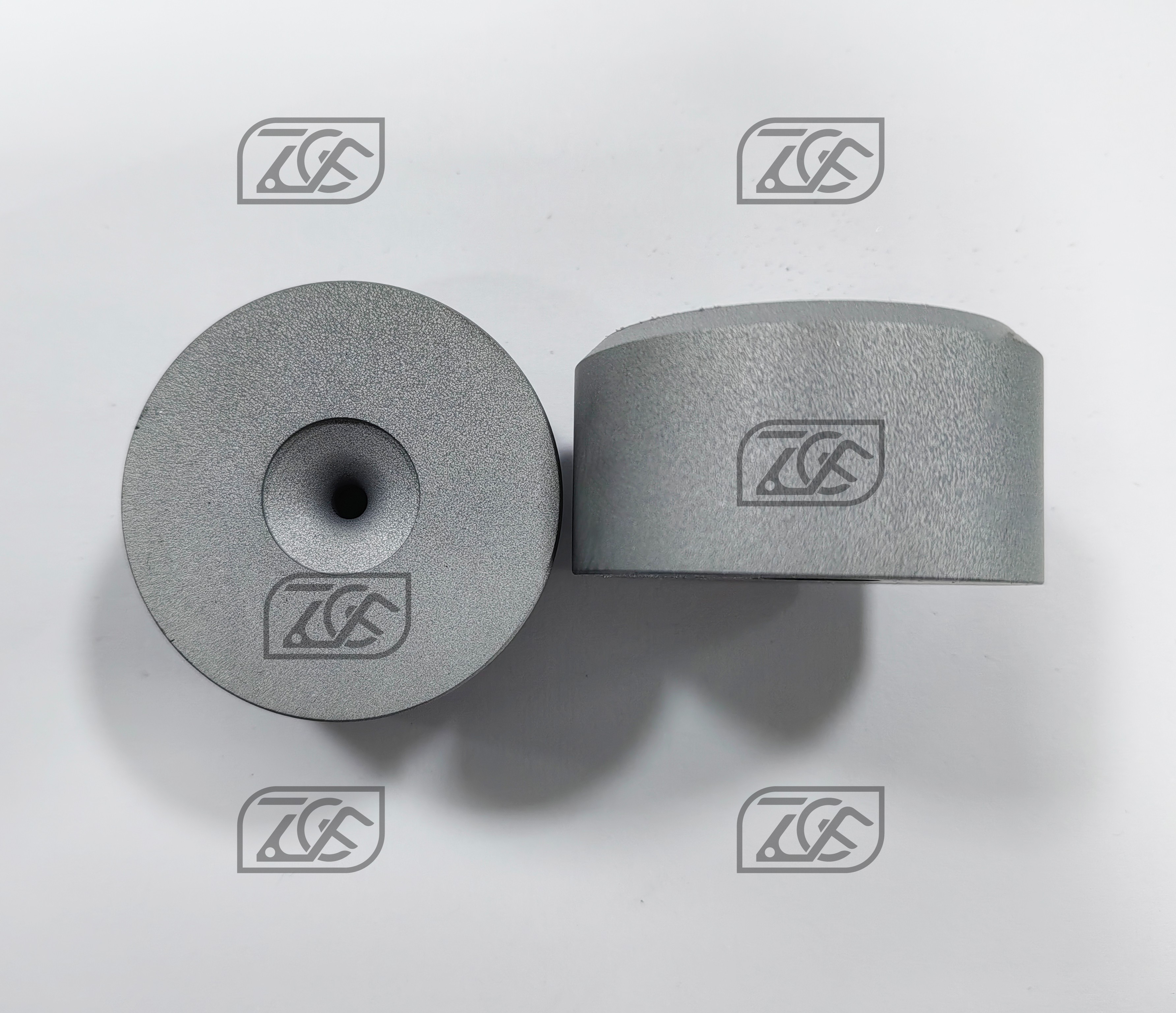

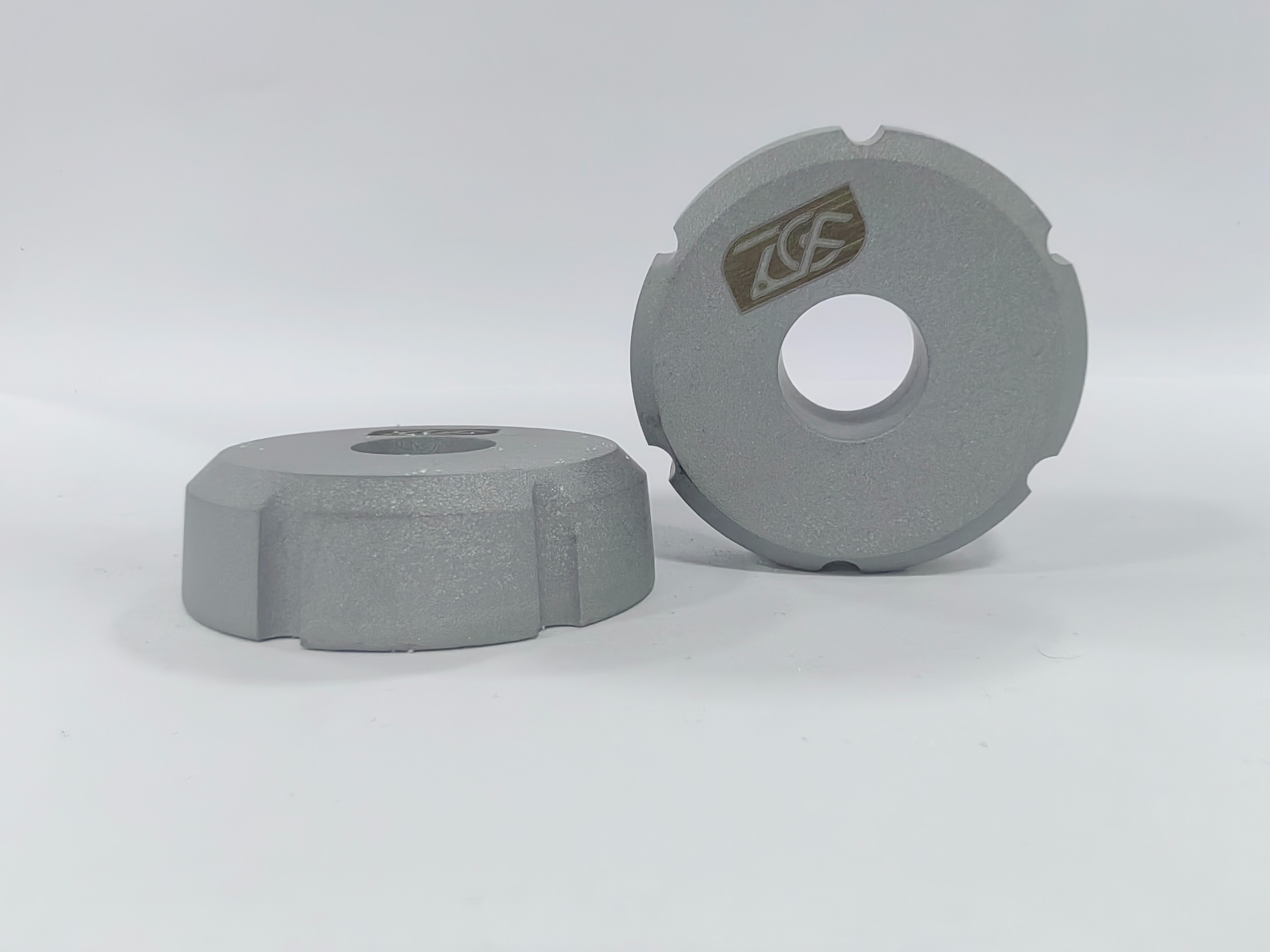

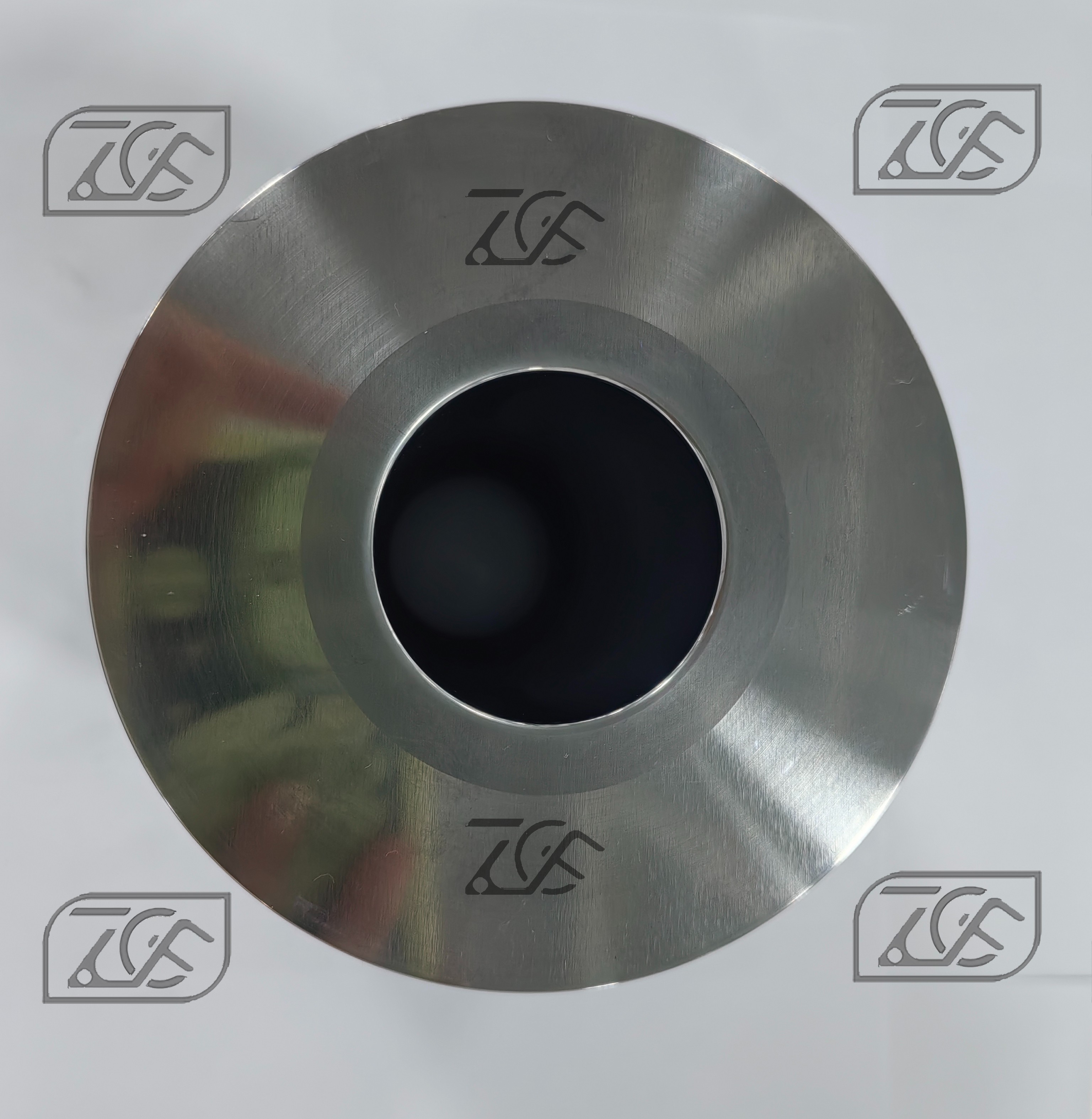

Introduction In today's era of rapid manufacturing development, molds, as fundamental industrial process equipment, directly determine the precision, performance, and cost of final products. Tun...

[ Learn More 」

Introduction Tungsten carbide (cemented carbide), known for its exceptional hardness (above HRA90), wear resistance, and corrosion resistance, is widely used in high-precision applications...

[ Learn More 」

Introduction Tungsten carbide molds are widely used in industries such as automotive, aerospace, electronics, and precision manufacturing due to their exceptional hardness, wear resistance, and ...

[ Learn More 」

Wire-cut Electrical Discharge Machining (EDM) is a highly precise manufacturing process used to cut complex shapes and intricate designs in conductive materials. While modern wire-cut machines often e...

[ Learn More 」

Introduction Tungsten carbide (WC) is a critical material in various industries due to its exceptional hardness, wear resistance, and durability. It is widely used in cutting tools, mining equip...

[ Learn More 」

In the world of precision manufacturing, achieving micron-level accuracy and flawless surface finishes is critical for industries like aerospace, medical devices, and advanced tooling. Among the vario...

[ Learn More 」

Introduction In today's fast-evolving industrial landscape, manufacturers face increasing pressure to improve efficiency, reduce costs, and maintain high-quality production. Enterprise Resource ...

[ Learn More 」

Tungsten carbide (WC) is one of the hardest and most durable materials used in industrial applications today. Composed of tungsten and carbon atoms in a rigid lattice structure, it offers exceptional ...

[ Learn More 」

Introduction Tungsten carbide is a critical material widely used in mold manufacturing due to its exceptional hardness, wear resistance, and thermal stability. However, the production of high-qu...

[ Learn More 」

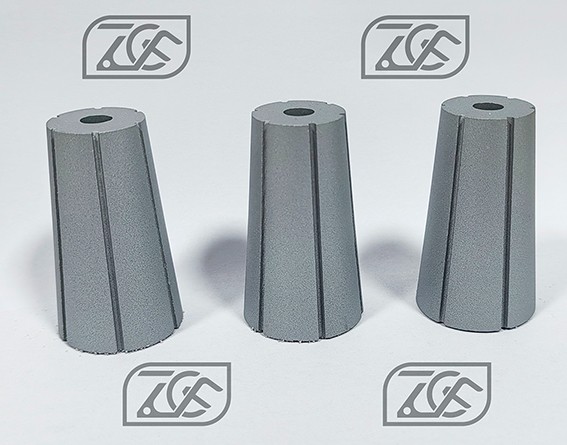

Introduction Fasteners, such as screws, bolts, and nuts, are essential components in industries ranging from automotive to construction. The production of these fasteners relies heavily on preci...

[ Learn More 」

Introduction Tungsten carbide (WC) is a highly durable and wear-resistant material widely used in industrial applications, particularly in molds and dies for metal forming, cutting, and wear-res...

[ Learn More 」

In the competitive global market for tungsten carbide (WC) molds and materials, where precision, durability, and reliability are essential, a robust quality management system (QMS) is crucial for succ...

[ Learn More 」

In the world of precision engineering, where micron-level accuracy separates exceptional performance from mediocrity, slow wire processing technology has emerged as a game-changer for tungsten carbide...

[ Learn More 」

In the highly specialized and competitive manufacturing industry, the production of tungsten carbide molds and dies demands precision, efficiency, and seamless coordination across various stages of th...

[ Learn More 」

Introduction: In the hallowed halls of industrial metallurgy, where science and craftsmanship converge, there exists a transformative process that borders on alchemy. The sintering furnace - this un...

[ Learn More 」

Introduction Tungsten carbide (WC) is a highly durable and wear-resistant material widely used in industrial applications, particularly in molds and dies for manufacturing processes. The perfor...

[ Learn More 」

Introduction The manufacture of tungsten carbide tools and materials is a highly specialized process that requires precision, consistency and adherence to strict technical specifications. Tungst...

[ Learn More 」

Introduction Tungsten carbide (WC) is a highly durable and wear-resistant material widely used in industrial applications, particularly in mold manufacturing. Tungsten carbide molds are essentia...

[ Learn More 」

Abstract Tungsten carbide (commonly referred to as cemented carbide or hard metal) is a critical material in mold manufacturing due to its exceptional hardness, wear resistance and thermal ...

[ Learn More 」